< Previous | Contents | Next >

Section 4 Acid Resisting Paints

401. Application

The requirements in this Section apply to tests and inspections for the type approval of acid resist- ing paints in accordance with the requirements of Pt 6, Ch 1, 1305. of the Rules.

402. Data to be submitted

The following reference data are to be submitted to the Society in addition to those specified in

102.

(1) Mixture ratio of main compositions for each symbol of products.

(2) Data for mixture and storage

(3) Instruction for painting (surface treatment, recommended dry film, thickness drying and over coating method, etc.)

(4) Marking

(5) In-house test results (approval certificates issued by other authorities, if any)

403. Type tests

![]()

Kind | Testing procedures |

Test specimen | The glass panel (about 150 mm × 70 mm × 2 mm) which is coated on both side is to be used as test specimen, unless otherwise specially specified. Four pieces of test panels are to be made according to coating method and drying condition designated by the manufacturer. The edges of three test specimens are to be duplicated with paraffin or wax, etc. at least 5 mm in width and one test panel is to be used for comparison. (refer to Fig 3.3.1) |

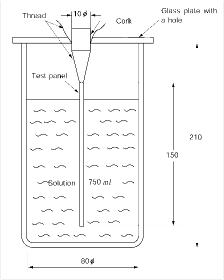

Test method | (1) A glass bottle for one test panel is prepared as shown in Fig 3.4.1 and each bottle is filled with acid solutions (5 %, 7.5 %, 10 %) designated by the manufacturer up to 150 mm in depth and then maintained the temperature of solution at designated temperature. The test panel is to be hung by thread so that it may be immersed up to 120 mm as shown in Fig 3.4.1 and left it immersed for 480 hours. After 480 hours, the test panel is removed from the glass bottle and washed carefully with water and then drained off. The test panel is placed perpendicularly at room temperature for two hours and paint film is examined. In this case, edge of test panel and paint film within 10 mm in width from the immersion level are not examined. Fig 3.4.1 Glass Bottle for Test (Unit : mm) |

Approval tests are to comply with the requirements given in Table 3.4.1. Table 3.4.1 Test details and acceptance criteria of acid resisting paints

application method,

![]()

Table 3.4.1 Test details and acceptance criteria of acid resisting paints (continued)

Kind | Testing procedures |

Test method | (2) The inlet of the glass bottle is to be properly faced and the hole of glass plate is plugged with a cork. The test panel is hung with two strings of thread fixed to it and penetrated through the gap between the glass plate and the cork. So the height of the test panel is adjusted by the length of the thread fixed to it. |

Acceptance criteria | Two test panels and over are to be examined with the test panel for comparison. In this case, paint film is to be free from cracks, blistering, peeling, pinholding, softening and elusion. There is to be no great change in color and gloss. |

404. Manufacturer approval

The manufacturer is to be subjected to Manufacturer approval in accordance with Ch 6.

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 73

![]()

![]()